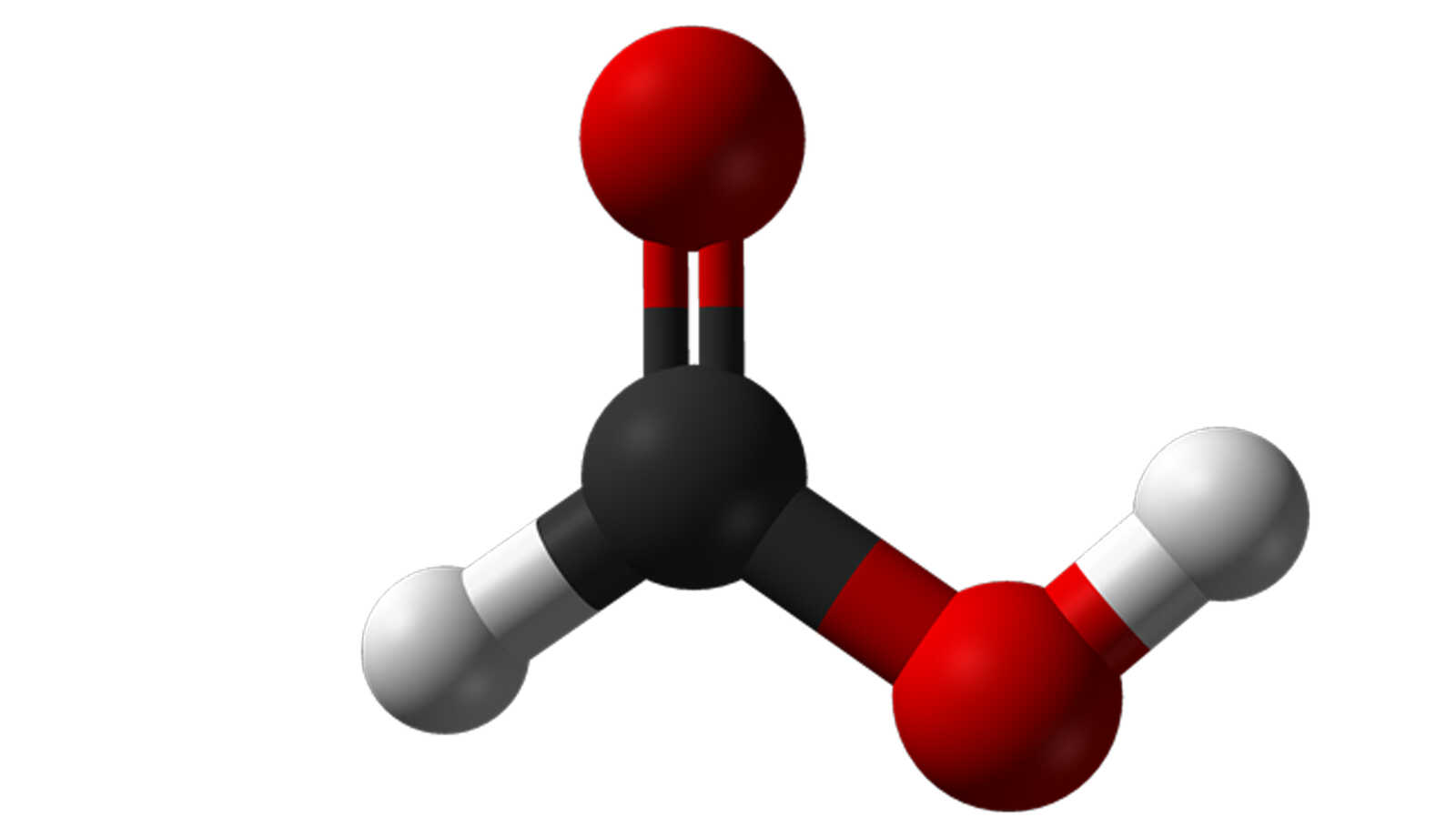

BASF: How will formic acid be synthesized in the future?

Reinventing a 50 year old process.

In March 2007, a team of about 60 people came to Biel/Bienne, Switzerland, to reflect on how to synthesize formic acid in the future. We used the BrainStore Idea Machine to brainstorm on chemical engineering processes. BASF went home with a set of great ideas and had since then implemented the ideas and built new production facilities.

To tackle this complex problem, we introduced our process to a team of talented chemical engineers and explained the BrainStore Idea Machine to them. They worked alongside our staff to ensure the chemistry knowledge was used properly within our process.

BrainStore then invited a diverse group related and unrelated to BASF: Chemistry students, chemistry professors from various nations, and external experts.

Thanks to the Ideamachine, we were able to create more than 1,000 raw ideas. Impressive! Our proven illumination phase allowed the experts to extract over 100 chemical synthesis ideas and finally selected ten that went into tests. Three of these were chosen for prototyping, and BASF has since implemented one of those three, creating a brand new production facility for formic acid.

This project allowed BASF to re-invent a production process that was 50 years old and to make it much more efficient and much less costly.